I have an original power feed on my Bridgeport Milling machine. Two of the gears in this transmission have broken teeth, and I decided to try and repair them. Here are the gears in question:

After cleaning up the gap a little, I brazed a big glob between the existing teeth. Yeah, first time brazing.

Then, after everything settled down, I stuck in the milling machine and cleaned up the edges a little with an endmill.

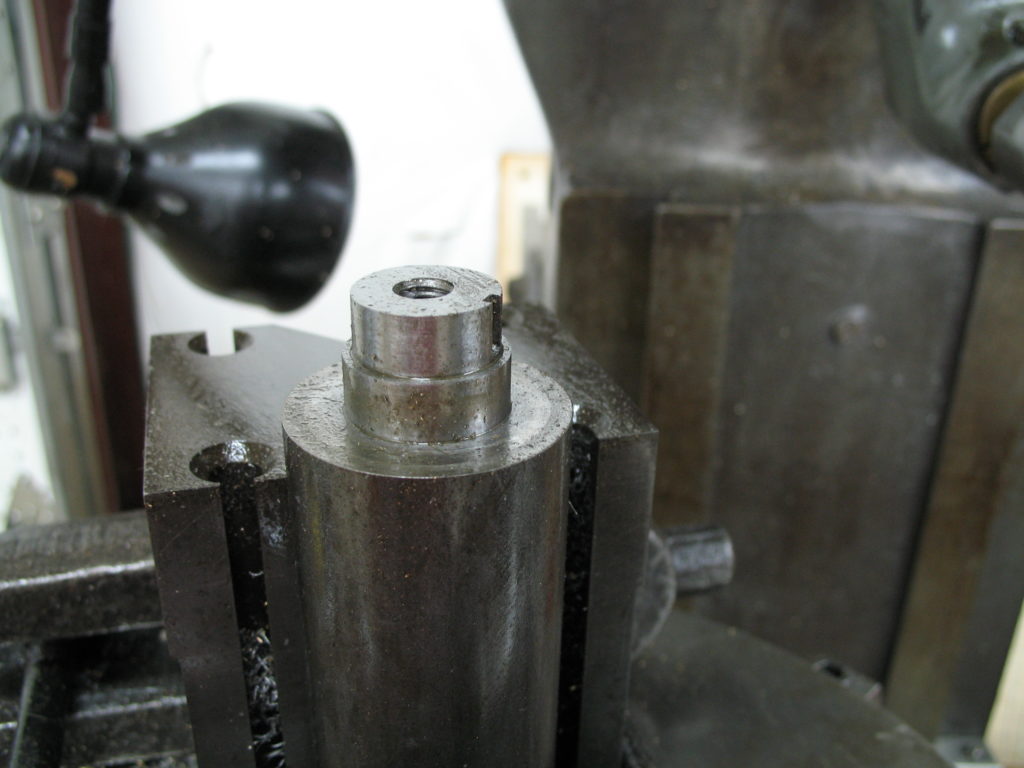

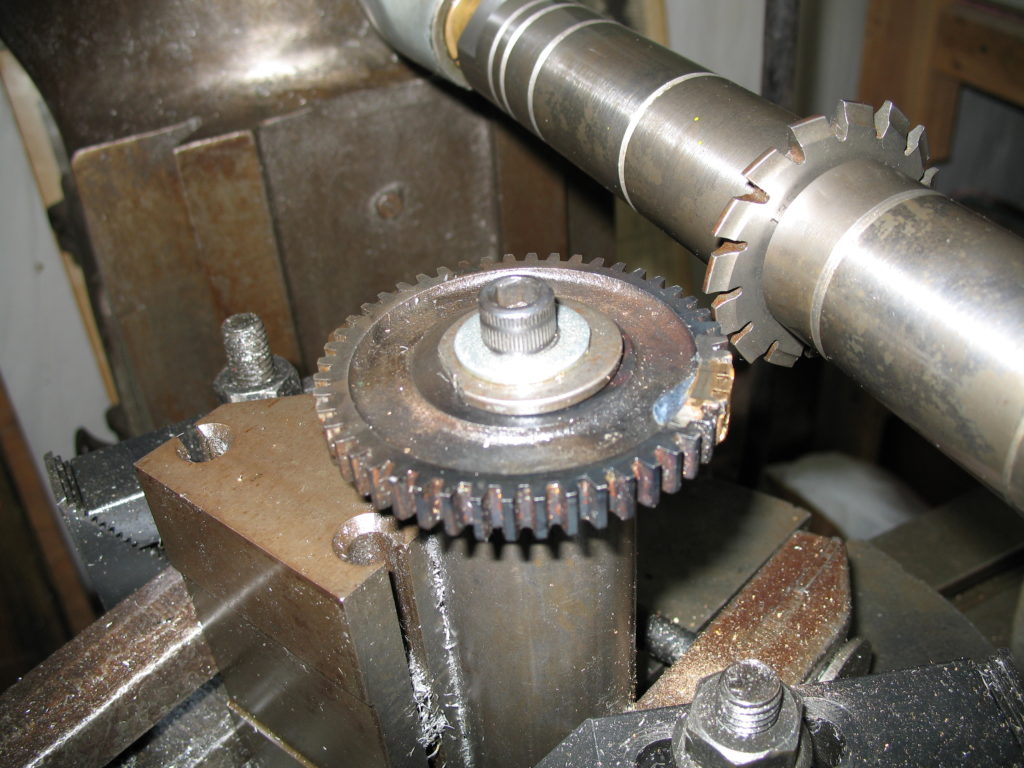

My plan for the cutting was to install a right-angle adapter on my mill, along with my rotary table. Then mount a round bar in the center of the rotary table. I cut it down to fit each gear, then threaded a hole in the top for a bolt, and milled a keyway to hold the gear in place. Here’s the setup (photo actually taken after the cutting):

So, up first, I’m going to install a gear, and make some preliminary cuts with a saw blade, in-between the new teeth. Then I’ll change to the gear cutter and go back in for a tooth-shaped cut. I’ve never cut gear teeth, and have no idea how it should be done. This may be obvious to the trained observer.

With some slots cut, I change out to the gear cutter, and line it up. I’m starting a couple of teeth before the cut, and “practicing” moving the table into the cutter on existing teeth. Then I rotate the table the proper angle, and go in to another. When I get to a new-tooth location, I power up and move in for the kill.

I think, at least, it LOOKS like legitimate gear teeth. Now to install them and check it out.

Thanks again for all the photos, I have mine completely torn down, cleaned, and almost ready to reassemble. I, too, have broken teeth, but on the two linked gears that live on the other spindle. What sort of gear cutter are you using? Not sure how those are spec’d.

I have a right-angle head for my mill, but this is the first time I’ve seen that horizontal support that connects to the ram. What are those called? Need to start searching ebay…

Hey Todd,

That’s the arbor support, and it supports the other side of the arbor. I got my pieces individually (right angle adapter, then arbor support, then arbor) over the years, and the biggest issue I had was getting the correct diameter arbor (as dictated by the arbor support). I can’t recall from memory what mine was (1 1/8″ or something), but most of the arbors being sold were about 1/16″ different. So I bought one that didn’t fit, and then had to spend quite a bit of time to find an auction for the specific measurement. My arbor support must have been older or something.

I don’t think you can use the arbor without the arbor support, because it’s too long. But, you may be able to cut the gear teeth with just the right angle adapter — if you can get the clearance you need. Depends on how you secure the gear to the table. I probably went overboard with that setup I used, but I wanted to be able to use the rotary table and get multiple teeth cut, with just one setup. I think it ended up working ok.

As for the gear cutters, I had purchased a big lot of cutters at a machine shop auction, and there were quite a few gear cutters. Gear cutters have very specific measurements which describe the shape of the teeth they cut. It’s all about diametric pitch, and pressure angle, and other things. So you determine the pressure angle, pitch, number of teeth on the gear, etc., and select a gear cutter based on that info. The gear cutter(s) are organized by sets. A particular tooth pattern may have 8 or 9 cutters in the set. For my project, there was no way I was gonna spend a lot of money on a gear cutter or set of cutters, so I just held a bunch of cutters up to the gear one by one, and found one that fit really well. I wouldn’t normally want to say it this way — but it seemed close enough!

I’ll look tonight and see what info I have on the right angle adapters, and let you know what I find.

That makes a lot of sense. I started trying to figure out gear cutters and quickly determined that I was in waaaaay over my head. Since this is really a hobby machine, i doubt that being close enough will prove to be a problem. And I, too, will learn both brazing and gear cutting on this little escapade.

Thanks for all the help!